Starting a 3D printing business can be both exciting and rewarding, offering a chance to work with new technology and create unique products. This guide will give you helpful tips and insights to get you started. You’ll learn the basics of 3D printing, including different types of technology and materials, as well as the financial aspects of setting up your business. By the end of this guide, you’ll have a clear path to starting and growing a successful 3D printing business.

Stage 1: Learning the 3D printing essentials

In this stage, you’ll learn about the basics of 3D printing and the materials you can use for 3D printing.

Step 1: Learning the basics of 3D printing

3D printing fundamentals

3D printing, also known as additive manufacturing, creates objects by adding material layer by layer. This is different from traditional methods like cutting or drilling where material is removed to create a shape.

Here’s how it works step-by-step:

- Design a model: Use CAD software to create a 3D model of the object you want to print. Alternatively, you can scan an existing object with a 3D scanner.

- Slice the model: Convert the 3D model into layers using slicing software.

- Print: The 3D printer follows the layers, building up the object from the bottom to the top.

3D printing can be used in various fields like prototyping, manufacturing, healthcare, and even art.

Materials for 3D printing

Choosing the right material is crucial for the success of your 3D printing project. Here are some common materials:

- PLA (Polylactic Acid):

- Biodegradable and derived from renewable resources.

- Easy to print and suitable for beginners.

- Not very heat-resistant.

- ABS (Acrylonitrile Butadiene Styrene):

- Strong and durable.

- More heat-resistant than PLA.

- Requires a heated print bed.

- Resin:

- Used in SLA printing.

- Offers high detail and a smooth surface finish.

- Requires post-print curing.

- Nylon:

- Used in SLS printing.

- Known for its strength and flexibility.

- Suitable for functional parts.

Make sure to select the material that best fits the needs of your project to achieve the best results.

Step 2: Creating a business plan

A strong business plan is essential. Begin by outlining your business objectives and goals. Include details like your target market, pricing strategy, and expected revenue.

Key components of your business plan:

- Executive summary: Provide an overview of your business concept.

- Market analysis: Identify your target customers and their needs.

- Product line: Describe the 3D printing services you will offer.

- Marketing strategy: Explain how you will attract and retain customers.

- Financial plan: Include a budget, projected income, and expenses.

A detailed plan helps you stay organized and focused.

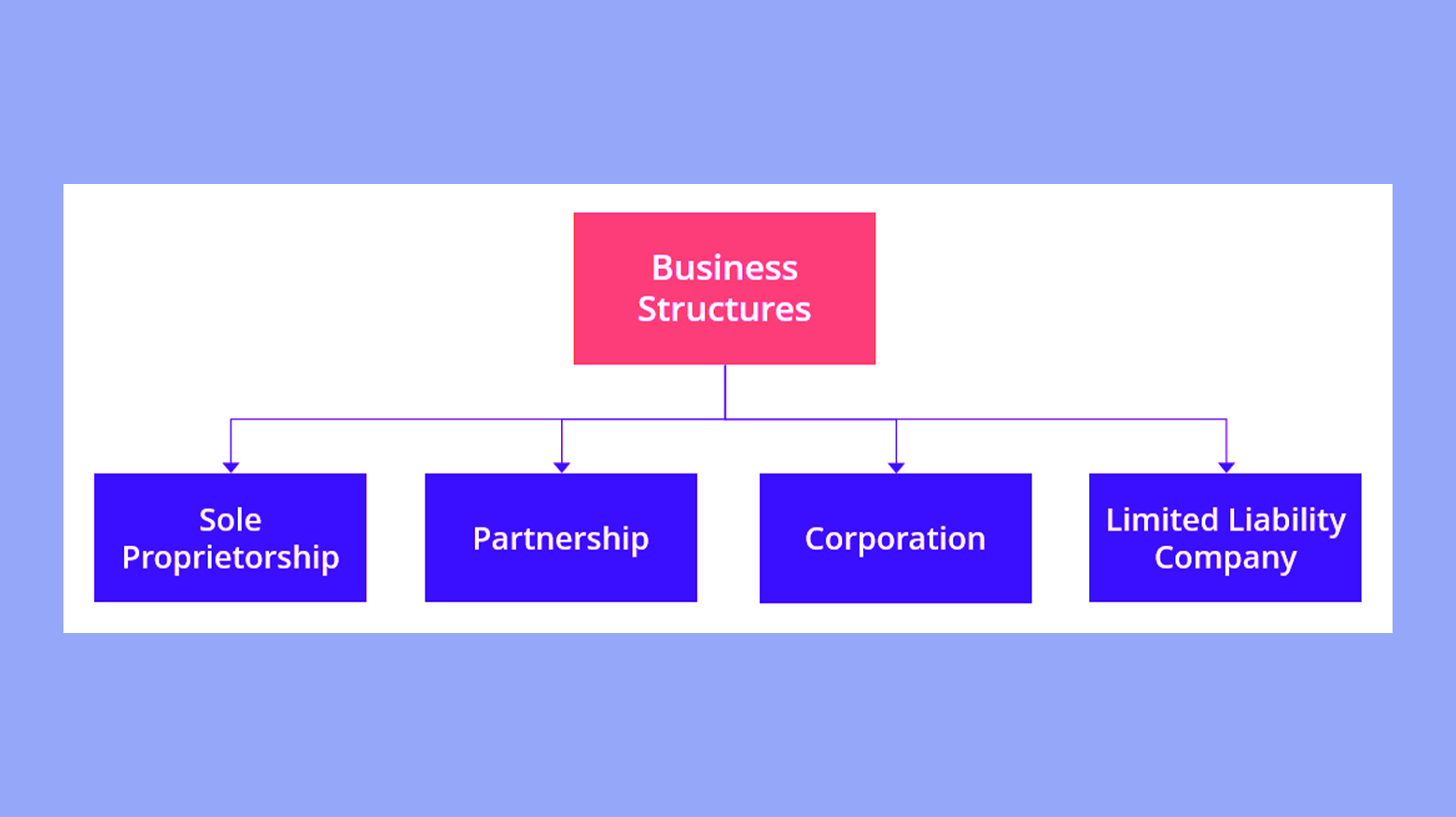

Step 3: Business registration and legal structure

Registering your business is crucial for legal operation. Choose a legal structure that best suits your needs, such as a sole proprietorship, partnership, or LLC. Each has different implications for taxes and liabilities.

Steps to register your business:

- Choose a name: Select a unique name for your 3D printing business.

- Register your business: File the necessary paperwork with your state or local government.

- Obtain an EIN: Apply for an Employer Identification Number (EIN) from the IRS.

- Apply for licenses and permits: Make sure you meet all local and state requirements.

Completing these steps ensures your business complies with regulations and operates smoothly.

Step 4: Learning the financial aspects

Starting a 3D printing business involves planning your budget, understanding costs and revenue, and exploring funding and financing options.

Setting up your budget is crucial. Identify all necessary costs such as equipment, materials, software, and rent. Think about initial investments in 3D printers and other essential technology. Include smaller expenses like marketing and office supplies.

Be sure to allocate funds for unforeseen expenses. This can prevent financial hiccups and ensure smoother operations. Keeping a detailed and realistic budget helps you stay on track financially.

Step 5: Understanding costs and revenue

Your costs include fixed expenses like rent and utilities, and variable expenses like raw materials and electricity. Estimate your monthly operational costs. Regularly update this to reflect any changes in pricing or volume of work.

Expected revenues should be realistically forecasted. This includes money from printing jobs, design services, or any other related services you offer. To determine a strong profit margin, understand how much you need to charge for your services to cover all costs and earn a profit.

Looking to sell online?

Create your custom online store in minutes with 10Web AI Ecommerce Website Builder and take your business online.

Stage 2: Setting up your 3D printing business

To set up your 3D printing business, you need a well-defined business plan, thorough market research, and proper legal registration. These steps help you create a solid foundation.

Step 1: Market research

Thorough market research helps you identify your target. Study your competition and understand their strengths and weaknesses. Look for gaps in the market where you can offer unique solutions.

Steps for effective market research:

- Identify competitors: Research other 3D printing businesses in your area.

- Analyze demand: Determine the demand for various 3D printing services.

- Survey potential customers: Gather feedback from your target market.

Selecting a niche, such as custom jewelry, prototype development, or medical devices, can help you stand out and attract specific customer groups.

Step 2: Creating a unique brand identity

Creating a strong brand identity is essential for differentiating your 3D printing business from competitors. Key elements include choosing a memorable business name and designing a distinctive logo, along with developing a unique selling proposition (USP) that clearly communicates the value you offer.

Choosing your business name and logo

Choosing the right business name is crucial. It should be memorable, easy to spell, and reflective of what your business does. Brainstorm keywords related to 3D printing, innovation, and creativity. Combine these keywords to create a name that stands out.

You can try using the 10Web business name generator. All you have to do is just give a hint and you will get business name ideas in seconds.

Once you have a list of potential names, check their availability. Ensure the name isn’t already in use by another company and that the corresponding domain name is available for building your website.

Designing a logo is the next step. Your logo should be simple, visually appealing, and represent the nature of your business. Use colors that evoke professionalism and innovation, such as blue or green. Hire a professional designer if possible, or use online tools like Canva or LogoMaker to create your logo.

Make sure your logo is versatile. It should look good on business cards, websites, and social media profiles. A well-designed logo helps customers recognize and remember your business.

Developing a unique selling proposition

A unique selling proposition (USP) sets your business apart from others. Your USP should clearly state what makes your 3D printing business unique and why customers should choose you over competitors.

Start by identifying your target market. Consider their needs, preferences, and pain points. Then, highlight the specific benefits your business offers. These could include faster turnaround times, higher-quality prints, or specialized services like custom designs.

Craft a concise and compelling statement that encapsulates your USP. For example, “We provide fast, custom 3D printing solutions for small businesses” clearly communicates your value. This statement should be prominently featured in your marketing materials and on your website.

Continuously refine your USP based on customer feedback and market changes. A strong USP not only attracts new customers but also builds loyalty among existing ones.

Step 3: Setting up production and manufacturing

Setting up production and manufacturing for a 3D printing business requires careful planning. Focus on choosing a suitable workspace, understanding the different production processes, and keeping your equipment in good shape.

Workshop and space considerations

A well-organized workshop is essential. Choose a space that fits your 3D printers, storage for materials, and a clean area for post-processing work. Ventilation is crucial, especially if you work with materials that produce fumes.

Identify areas for specific tasks. For example:

- Printing area: Enough room for printers and easy access.

- Storage: Shelves and cabinets for materials and tools.

- Post-processing zone: Space for cleaning and finishing parts.

Ensure your workspace has adequate power outlets and proper lighting to work effectively.

Maintaining printing equipment

Regular maintenance keeps your 3D printers in top condition. Check and clean the print bed, nozzles, and extruder regularly to prevent clogs. Lubricate moving parts to ensure smooth operation.

Schedule periodic deep cleanings and calibrations. Replace worn out parts like build plates or nozzles to maintain print quality. Keep firmware updated to take advantage of new features and fixes.

Document your maintenance routines in a log. This helps track what has been done and when it needs to be done again. Proper maintenance ensures consistent production and extends the life of your printing equipment.

Step 4: Managing business operations

To effectively run a 3D printing business, it’s crucial to manage financials, ensure staff is well-trained, and maintain excellent customer relations. These areas are vital to ensuring smooth operations, monitoring profitability, and providing great service.

Handling finances and accounting

Properly managing your finances is key to the success of your 3D printing business. Start by setting up a business bank account to keep personal and business finances separate. Use accounting software like QuickBooks or FreshBooks to track income, expenses, and generate financial reports.

Create a budget to control spending and forecast cash flow. Keep track of all receipts and invoices for tax purposes. Hire an accountant for complex financial tasks or tax preparation to ensure compliance and avoid penalties.

Maintain detailed records of all transactions and frequently review your financial performance to spot trends or areas for improvement.

Staffing and training

Hiring the right team and providing them with the necessary training is critical. Begin by identifying the roles you need, such as designers, machine operators, and marketing specialists. Post job openings on platforms like LinkedIn, Indeed, or local job boards.

Once hired, ensure that new employees undergo comprehensive training on the specific 3D printers and software you use. Regularly organize workshops or training sessions to keep staff updated on the latest technologies and practices.

Encourage a culture of continuous learning and innovation. Providing your team with the skills they need to excel will improve overall productivity and the quality of your products, driving profitability and growth.

Step 5: Acquiring 3D printers and software

Selecting the right 3D printer, CAD/CAM software, and sourcing the necessary materials are crucial steps for starting a 3D printing business. You’ll want equipment that meets your needs in terms of quality, cost, and functionality.

Types of 3D printing technology

There are several types of 3D printing technology, each suited for different needs:

- Fused deposition modeling (FDM):

- This is the most common type and is ideal for beginners.

- It works by extruding melted plastic filament layer by layer.

- Commonly used filaments include PLA and ABS.

- Stereolithography (SLA):

- Uses a laser to cure liquid resin into hardened plastic.

- Known for producing high-detail and smooth finishes.

- Suitable for making intricate and delicate models.

- Selective laser sintering (SLS):

- Uses a laser to sinter powdered material, usually nylon.

- It’s great for creating strong and durable parts.

- Often used in industrial applications.

Step 6: Selecting CAD/CAM software

CAD (Computer-Aided Design) software is essential for creating the models you’ll print. AutoCAD and SolidWorks are industry standards. Fusion 360 is user-friendly and integrates well with many 3D printers. Blender is a good free option with lots of features.

For CAM (Computer-Aided Manufacturing), you have Cura which is popular slicing software that converts CAD models into 3D printer-friendly codes. PrusaSlicer and Simplify3D are other options. Make sure your software is compatible with the materials and 3D printers you use. Learning to use these tools effectively can greatly impact your print quality and efficiency.

Step 7: Sourcing materials and tools

You need high-quality materials to produce reliable and attractive products. Plastics like PLA, ABS, and PETG are common and come in various colors and finishes. Resins are needed for SLA printers and come in different types based on your project requirements. Metal powders are used for metal 3D printing.

Purchase from reputable suppliers to ensure material consistency. You will also need tools like calipers for measuring dimensions, spatulas for removing prints from the build plate, and storage solutions to keep your materials moisture-free. Proper sourcing helps maintain print quality and reduces costs in the long run.

Looking to sell online?

Create your custom online store in minutes with 10Web AI Ecommerce Website Builder and take your business online.

Stage 3: Building online presence and marketing strategies

Creating a strong online presence and an effective marketing strategy is crucial for the success of your 3D printing business. Focus on building a solid website, leveraging social media platforms, and incorporating offline marketing strategies.

Step 1: Building an online presence

Your website is the first point of contact for many potential customers. Make sure it is well-designed, easy to navigate, and includes essential information about your services.

- Design and usability: Use a clean design and ensure the site is mobile-friendly.

- Content: Include detailed descriptions of your services, prices, and examples of your work.

- SEO: Optimize your website with good keywords. This helps improve your search engine ranking.

- Contact: Provide clear contact details and a contact form to make it easy for customers to get in touch.

Creating an online platform for your business with 10Web is simple and efficient. You have two options to get started:

- Provide 10Web AI Website Builder with a link to a design you like, and it will create a similar one for you.

- Answer a few questions about your business to generate a website from scratch.

For this example, let’s go with the second option:

- Go to the 10Web Website Builder page and click Generate your website.

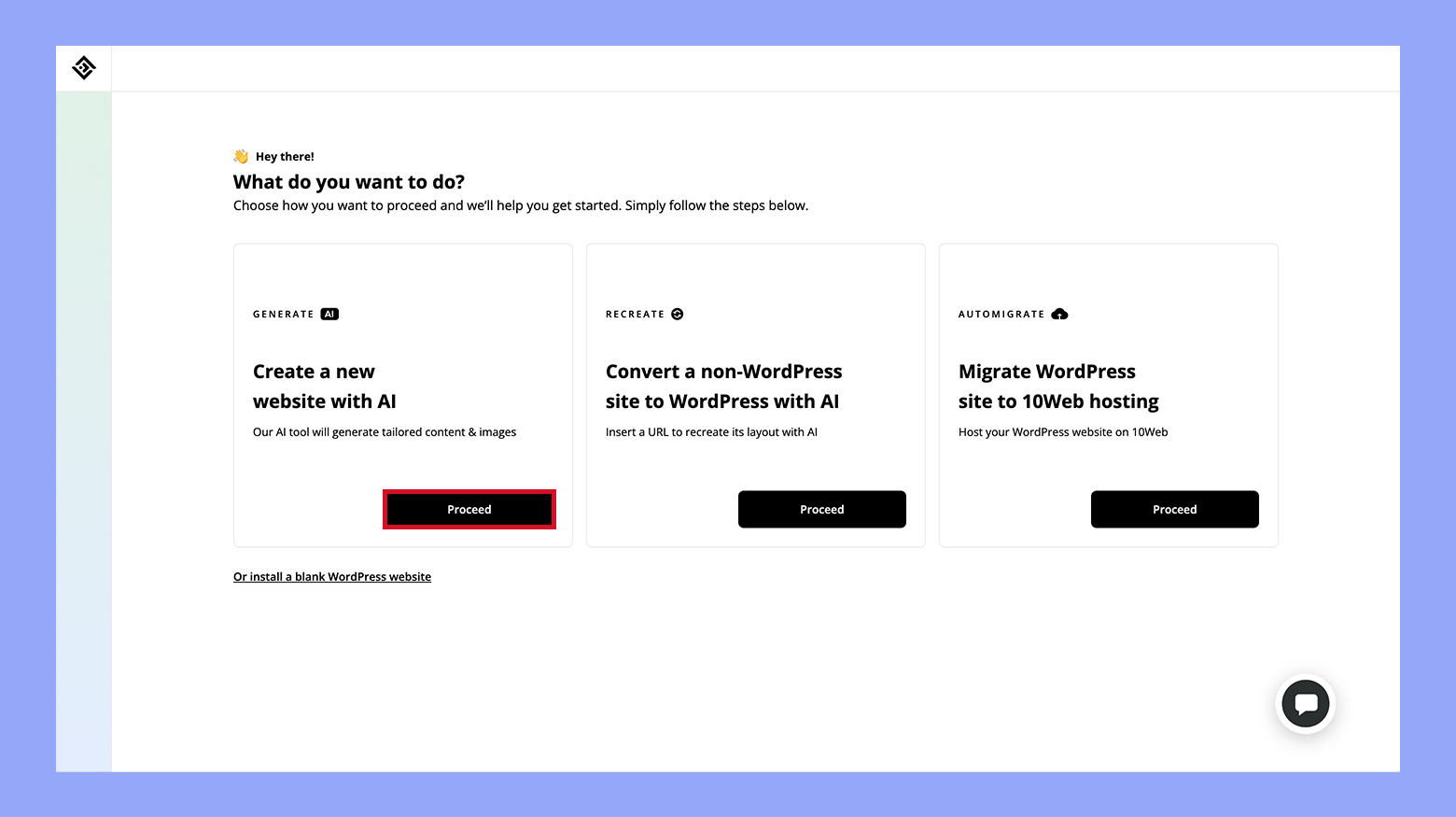

- Select Proceed to create a new website with AI.

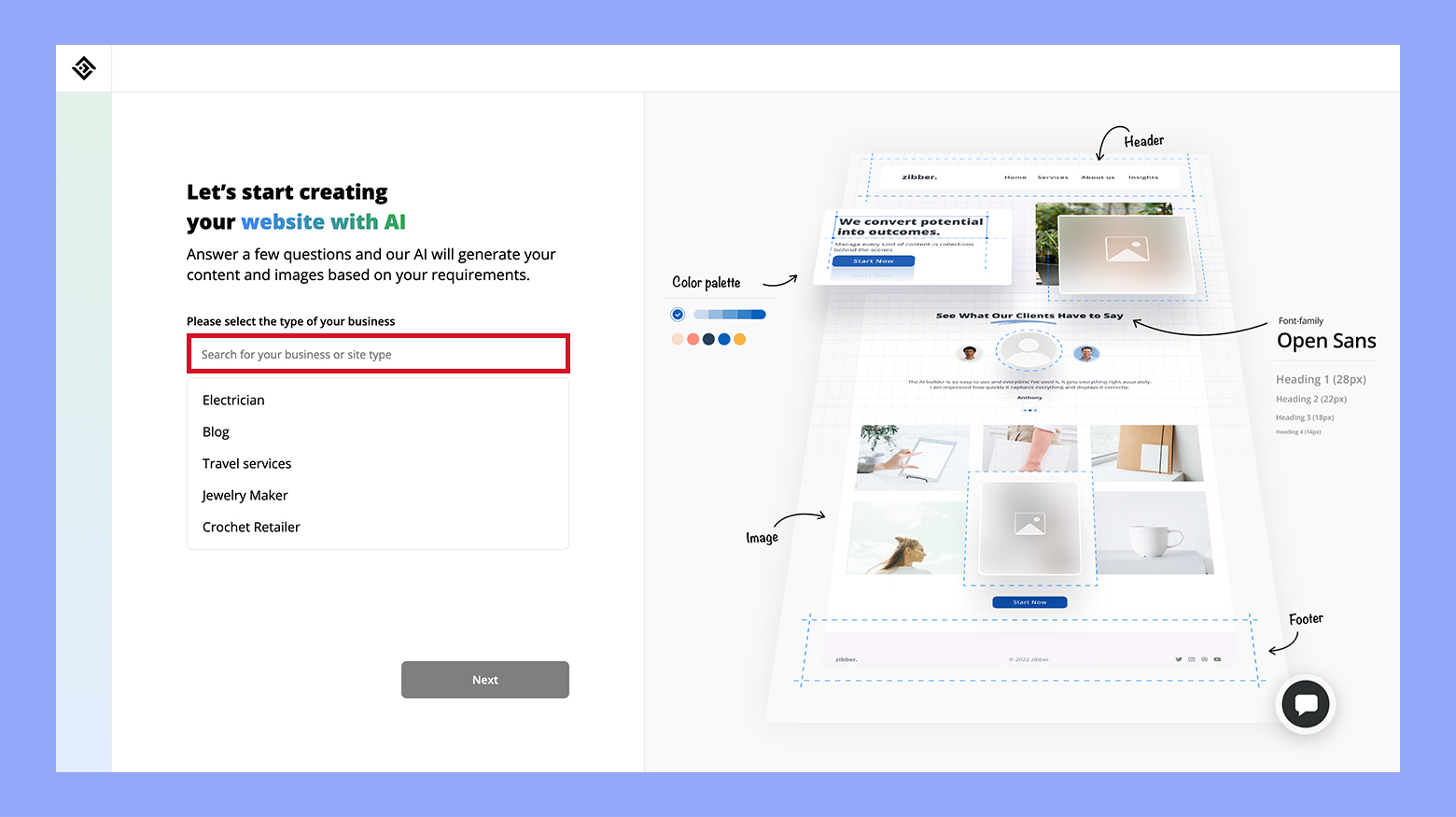

- Enter your business type.

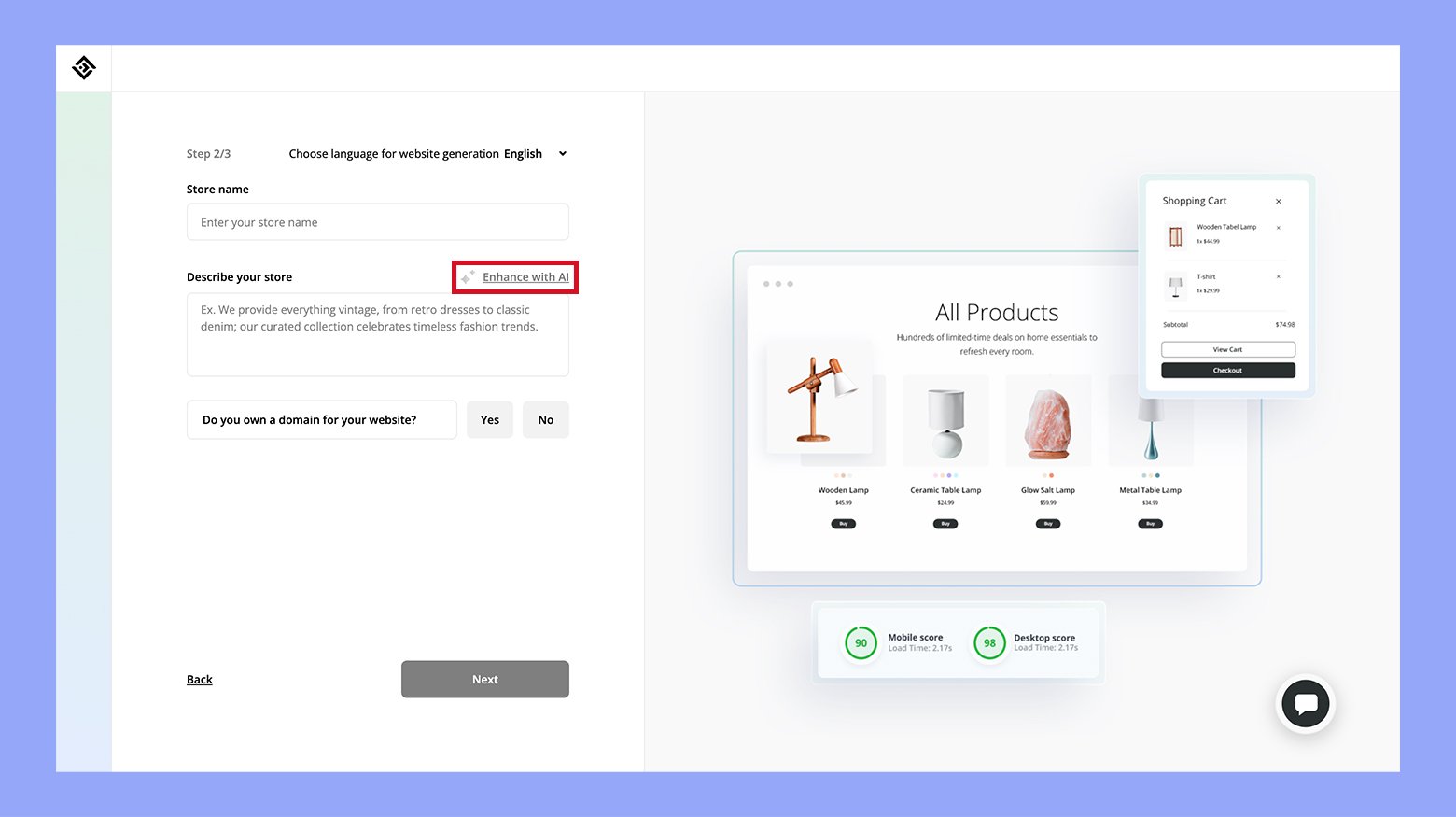

- Provide a business name and description. Use the Enhance with AI tool if needed.

- Choose Yes to get a domain or click No if you have one already.

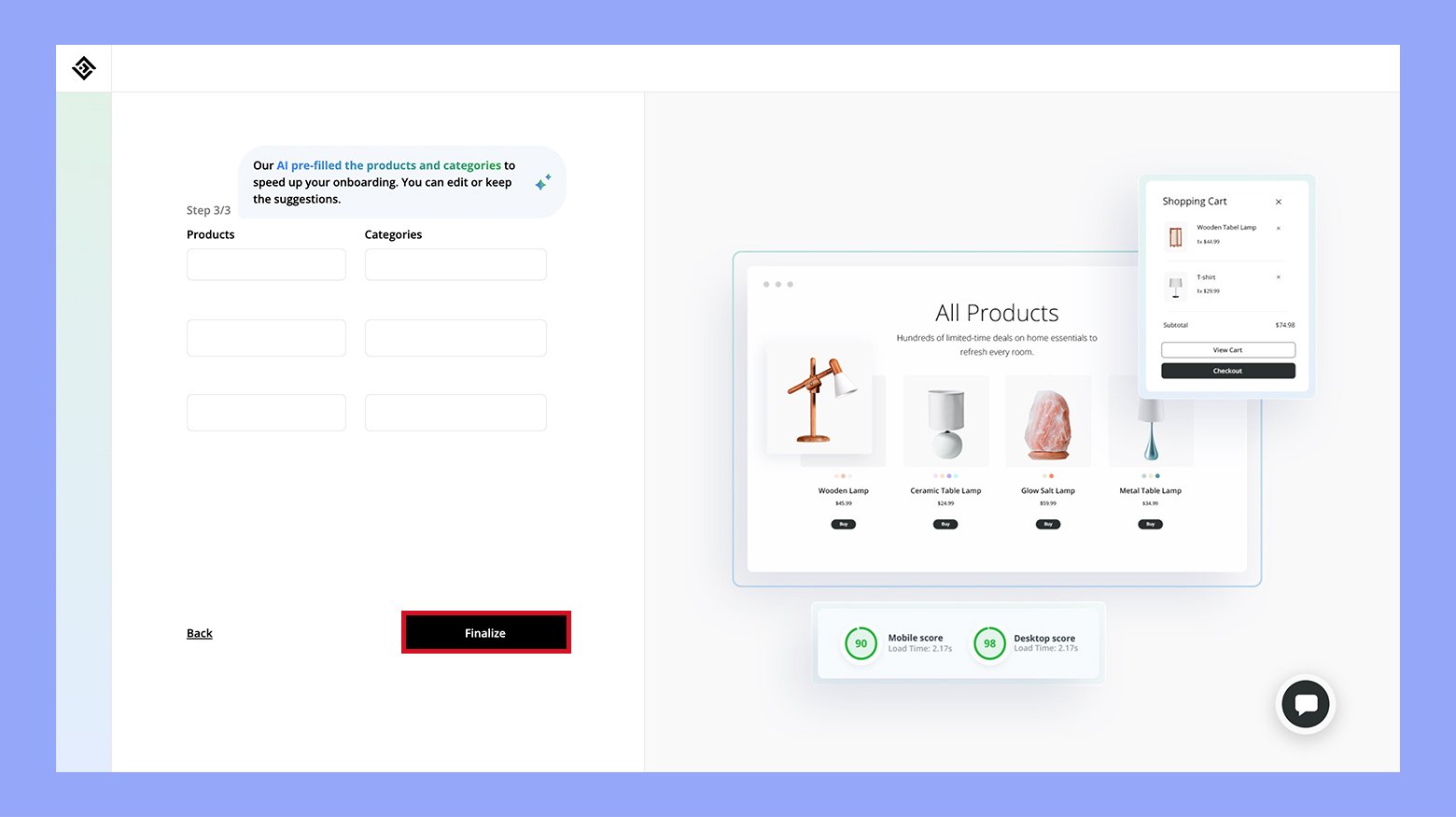

- Enter details for your first three services and categories. AI will pre-fill them for you, you can edit or keep the suggestions. When done, click Finalize, and wait for 10Web to generate your site.

- Once your site is generated, preview it and make any necessary adjustments using the user-friendly tools provided by 10Web.

Step 2: Leveraging social media platforms

Social media is a powerful tool to reach potential customers. Focus on platforms where your target audience is most active.

- Facebook: Create a business page, share photos of your work, and engage with your followers.

- Instagram: Post high-quality images and short videos of your 3D prints. Use relevant hashtags to increase visibility.

- LinkedIn: Connect with other professionals and join industry groups to network and showcase your expertise.

Use social media ads to target specific audiences and increase visibility. Consistent posting and engagement are key to building a loyal following.

Step 3: Offline marketing strategies

While online efforts are essential, do not overlook offline marketing strategies to expand your reach.

- Trade shows: Attend industry trade shows to network with potential customers and partners. Display your work and provide informational brochures.

- Local partnerships: Collaborate with local businesses and schools for joint projects or sponsorships.

- Flyers and business cards: Distribute flyers and business cards at local events and related businesses.

Combine these methods to create a well-rounded marketing strategy that covers both online and offline channels.

Scaling your 3D printing venture

As your 3D printing business grows, it’s crucial to measure growth, explore new opportunities, and implement sustainable practices. Each area will help you manage and expand your business effectively.

Measuring business growth

To scale your business, start by tracking key performance indicators (KPIs). Common KPIs include revenue, customer acquisition rates, and production output. Use software tools or spreadsheets to monitor these metrics regularly. You should also evaluate customer feedback and satisfaction to identify areas for improvement.

Consider setting realistic growth targets. For instance, aim to increase monthly sales by 10% or reduce production times by 15%. Achieving small, consistent goals will help you build momentum over time. It’s also helpful to benchmark your performance against competitors in the 3D printing market.

Exploring expansion opportunities

Expansion opportunities in 3D printing can include entering new markets or offering new products and services. Research and identify niches with high demand. For example, industries like healthcare or automotive often need specialized 3D printing solutions. You can explore both domestic and international markets.

Networking and partnerships are also essential for growth. Attend trade shows, join industry associations, and build relationships with suppliers and other businesses. These connections can open doors to new opportunities and collaborations. Lastly, invest in marketing strategies such as social media campaigns or email newsletters to reach a broader audience.

Sustainable business practices

Implementing sustainable practices is key to long-term success. Start by using eco-friendly materials and methods in your production process. For example, opt for biodegradable filaments when possible. Reducing waste and recycling excess materials can also make your business more sustainable.

Energy efficiency is another area to focus on. Invest in energy-efficient equipment and consider renewable energy sources for your operations. Educate your customers on the environmental benefits of your products, which can boost your reputation and attract eco-conscious clients.

By incorporating these practices, not only do you contribute positively to the environment, but you also appeal to a growing market of environmentally aware consumers.

Operational challenges and solutions

Starting a 3D printing business comes with its unique set of challenges. You will face rapid technological changes, supply chain complexities, and environmental concerns. Addressing these issues effectively is key to your success.

Dealing with technological changes

3D printing technology changes quickly. Staying updated is necessary to maintain your competitive edge.

To keep up, attend industry conferences and webinars. Subscribing to tech journals and blogs can also help. Learning about new materials and software tools will keep your services relevant.

Investing in staff training is essential. Ensure your team is skilled in the latest techniques and equipment. Regular workshops can bridge the skills gap.

Budget for equipment upgrades. This way, your business stays efficient and can produce high-quality prints. Having a dedicated research and development team can also help you stay ahead of the curve.

Managing supply chain

Efficient supply chain management is crucial for your 3D printing business. You need a steady supply of filaments, resins, and other materials to keep operations running smoothly.

Start with reliable suppliers. Vet your suppliers thoroughly to avoid delays and subpar materials. Building strong relationships can also help in negotiating better deals.

Maintaining an inventory management system is beneficial. A good system helps track material usage and reorder supplies before they run out. Using software for inventory management can streamline this process.

Diversify your supply chain sources. Relying on a single supplier can be risky. Having multiple suppliers ensures you will not face stockouts or delays if one supplier encounters issues.

Environmental considerations

3D printing has environmental implications that need your attention. Understand the environmental impact of your operations and try to minimize it.

Using eco-friendly materials can be a significant step. There are biodegradable and recyclable filaments available that reduce your carbon footprint. Always stay updated on new sustainable materials.

Waste management is also crucial. Implement a recycling program for your waste materials. Many suppliers offer programs to take back used filaments and resins for recycling.

Energy consumption should be monitored. 3D printers can be energy-intensive, so using energy-efficient models and operating them during off-peak hours can help reduce costs and environmental impact. Regular maintenance of printers ensures they run efficiently.

Conclusion

Starting a 3D printing business requires understanding the technology, careful planning, and strategic execution. By learning the basics, choosing the right equipment and materials, and creating a solid business plan, you can set a strong foundation for your venture. Effective market research and proper business registration are crucial steps to ensure your business operates smoothly. With dedication and continuous learning, you can navigate the challenges and capitalize on the opportunities in this innovative field.